Pile drivers

Refine Search

WS-01 Mini Hydraulic Impact Hammer Four Wheel Multi-functional Pile Driver

Products DescriptionMultifunctional Hydraulic Pile Driver IntroductionHydraulic Impact Pile Hammers Are A Modernized Version Of The Diesel Impact Hammer Which Use Hydraulic Power Packs As Its Fuel Sou..

WS-01 Model Professional Hot Motor Pump Highway Excavator Vibrating Hammer Hydraulic Pile Driver

Products DescriptionMultifunctional Hydraulic Pile Driver IntroductionHydraulic Impact Pile Hammers Are A Modernized Version Of The Diesel Impact Hammer Which Use Hydraulic Power Packs As Its Fuel Sou..

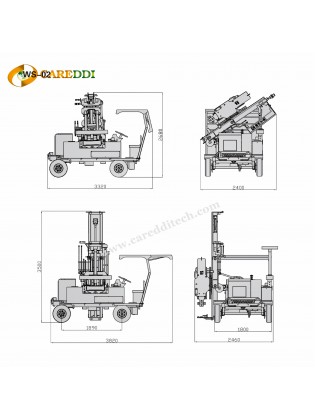

WS-02 Model Automatic Hammer Pile Driver For Highway Guardrail Instruction

Products DescriptionMultifunctional Hydraulic Pile Driver IntroductionHydraulic impact pile hammers are a modernized version of the diesel impact hammer which use hydraulic power packs as its fuel sou..

WS-02 Small Sheet Pile Driver Ground Screw Machine For Solar Photovoltaic Installation

Products DescriptionMultifunctional Hydraulic Pile Driver IntroductionHydraulic Impact Pile Hammers Are A Modernized Version Of The Diesel Impact Hammer Which Use Hydraulic Power Packs As Its Fuel Sou..

WS-03 Model Solar Power Panels Installers Highway Road Hydraulic Hammer Pile Driver

Products DescriptionMultifunctional Hydraulic Pile Driver IntroductionHydraulic Impact Pile Hammers Are A Modernized Version Of The Diesel Impact Hammer Which Use Hydraulic Power Packs As Its Fuel Sou..

WS-03 Useful Small Piling Equipment Customized Vibrate Hammer Hydraulic Pile Driver

Products DescriptionMultifunctional Hydraulic Pile Driver IntroductionHydraulic Impact Pile Hammers Are A Modernized Version Of The Diesel Impact Hammer Which Use Hydraulic Power Packs As Its Fuel Sou..

YDBZ-385 Model Hydraulic Pile driver Ground Loader For Contruction Process

Products DescriptionMultifunctional Hydraulic Pile Driver IntroductionHydraulic Impact Pile Hammers Are A Modernized Version Of The Diesel Impact Hammer Which Use Hydraulic Power Packs As Its Fuel Sou..

YDBZ385 Series Hot Sale Multifunctional Hydraulic Press Pile Driver Dig Foundation Machine

Products DescriptionMultifunctional Hydraulic Pile Driver IntroductionHydraulic Impact Pile Hammers Are A Modernized Version Of The Diesel Impact Hammer Which Use Hydraulic Power Packs As Its Fuel Sou..

What is a pile driver?

Pile driver drives steel, concrete or wood piles into the earth in the early stages of construction. Skill is critical to the success of the project and the safety of workers, as pile driving is necessary to hold down the soil during excavation and to build the foundations of skyscrapers, highways and bridges, as well as to construct piers and boat docks.

Pile drivers are essential mechanical devices often used in driving piles into soil to provide foundation support for buildings or other large structures like highways and dams. In some cases, pile drivers can also being used in underwater construction by professional commercial divers.

Nowadays, if we pay attention to the modern construction process, the most common piling methods are diesel impact hammer, vibratory hammer and hydraulic impact hammer. Some of these types of pile drivers can also drive wood piles and sheet piles as needed.

Types of pile drivers

According to the power source of movement, Careddi offers different types of piling drivers that are made in China with good quality. Now we mainly describe the following three main types of pile drivers.

Ⅰ. Diesel hammer pile driver

The diesel hammer pile driver uses the fuel explosion to push the piston, and the pile head is impacted by the explosion force to make the pile sink into the ground, which is suitable for driving all kinds of prefabricated piles. The main body is composed of cylinder and plunger, and its working principle is similar to that of single-cylinder two-stroke diesel engine, using the strong pressure generated by the atomized diesel fuel sprayed into the combustion chamber of the cylinder after high pressure and high temperature combustion to drive the hammer head. The work of diesel hammer is to rely on the compression of diesel to start, so it must ensure that the closed gas in the cylinder to achieve a certain compression ratio, sometimes in soft ground piling, often due to the reaction force is too small, the amount of compression is not enough to ignite the detonation, it is necessary to use the hook many times to lift the hammer head off the hook impact, in order to start. Technically speaking, diesel pile driver is also a kind of traditional drop hammer. The biggest feature of the drop hammer is its free-fall style, which can be used to drive all types of steel piles, In addition, diesel hammers do not require additional electrical support and can be self-sufficient, so they are very safe and reliable in construction and do not need to worry about special circumstances such as power outages. So, although the diesel pile driver was born earlier and the equipment is relatively traditional and old, because of its simple working principle, it is still popular and widely used in the modern construction process.

Ⅱ. Vibratory Hammer Pile Driver

Vibratory hammer pile driver uses the mechanical vibration force of pile hammer to make sure the vibratory piles sink into the ground and install the piles. Its unique design allows it to transfer its vibration to the pile itself due to the horizontal vibrations of the hammer are offset by vertical vibrations, resulting in changes in the soil structure around the pile and a reduction in strength. In the case of pile extraction, the pile is lifted by the uplift force of the excavator while vibrating on one side.

Therefore, the soil requirements of vibratory pile driver are complicated, usually considering the specific soil thickness of the construction site, soil quality, soil moisture content, as well as and the type of pile, construction, etc.. These factors need to be examined in advance before starting the construction. But as long as the construction conditions are met, the vibratory pile driver is actually better than other types and takes less time and noise to operate.

Vibratory hammer pile drivers are suitable for precast concrete piles and driving steel with small bearing. Especially for municipal construction, bridges, cofferdams, building foundations and other short and medium pile projects because the noise level is relatively low and meets most city standards.

Ⅲ. Hydraulic Hammer Pile Driver

The hydraulic pile driver is a domestic original equipment with independent intellectual property rights by introducing advanced technology from abroad.

The hydraulic impact pile driver is a modernized version of the diesel impact pile driver, which uses a hydraulic power pack as its fuel source. Hydraulic hammers are capable of driving not only steel piles such as pipes, slabs or beams, but also timber and precast concrete piles.

In addition to the ability of hydraulic hammers to drive steel, timber and precast concrete piles, this type of pile hammer is also considered to be more environmentally friendly than its diesel counterpart. Not only are there no exhaust gases emitted into the air, but the noise level of hydraulic hammers is also much lower than that of diesel hammers.

It is especially suitable for municipalities, bridges, cofferdams, building foundations and other short and medium pile projects. Low noise, in line with city standards.

What is a pile driver used for?

Our pile driver is a kind of construction machinery which is converted from hydraulic energy to mechanical energy, mainly used for the construction of highway guardrail steel pipe piles. It’s also used for screwing the solar auger pile into the ground, and with different bits it can also drill holes into the ground. The function is to prevent uneven settlement of the building, strengthen the stability, and earthquake resistance, etc.

Guardrail piling machine is a kind of highway guardrail steel pipe pile driving equipment, the machine adopts diesel power, full hydraulic mechanical transmission, with driving light, piling high precision, durable, energy saving and environmental protection, especially suitable for highway guardrail installation, maintenance and repair of field engineering construction.

How does a pile driver work?

The principle of construction type pile driver is divided into various types. Usually, diesel engine is used to push the weight to a certain height and then free fall using gravity to impact the top of the pile and the pile naturally sinks into the soil, thus repeating the cycle until the design elevation. Static piles are pressed into the soil by the mechanical force of the pile top.

The key driving force of guardrail piling machine is to use the impact force to touch the pile to the ground, and then use the method of hydraulic machine sensing technology to promote the work of mechanical equipment. In that way, the user's work efficiency is guaranteed, along with high quality of opening holes and low energy consumption.

_副本-315x420.jpg)

-315x420.jpg)