Careddi Technology Co.,Ltd. is a large enterprise specialized in developing and manufacturing all kinds of complete sets of

equipment for crushing and grinding waste tires and rubber products, with a registered capital of 21 million yuan, an area of more

than 40,000 square meters, a building area of more than 29,000 square meters, and a variety of modern processing equipment and testing instruments.

XPZ Series Rubber Secondary Crusher Further Crushing Coarse Rubber Granules Directly In Use

Products Description

The role of Tyre Recycling Plant

Nowadays, whether in developed or developing countries, more and more individuals or families choose to buy a car or more because of improved economic ability and cheaper prices of the vehicles.

Correspodningly, tyre scarp has been increasing greatly. Tyre recycling plant is quite need for eco-friendly environment.

Correspodningly, tyre scarp has been increasing greatly. Tyre recycling plant is quite need for eco-friendly environment.

Scrap Tyre Recycle Complete Production Line for Rubber Fine Powder

The Technological Flow:

Step 1. Whole Tire

Step 2. Remove Bead

Step 3. Cut tire into tire lumps

Step 4. Get rubber granule after crushing, metal-removing and fiber-separation.

Step 5. Get rubber fine powder after grinding

Step 6. Classify by sieveing

Step 7. packing

Details Images

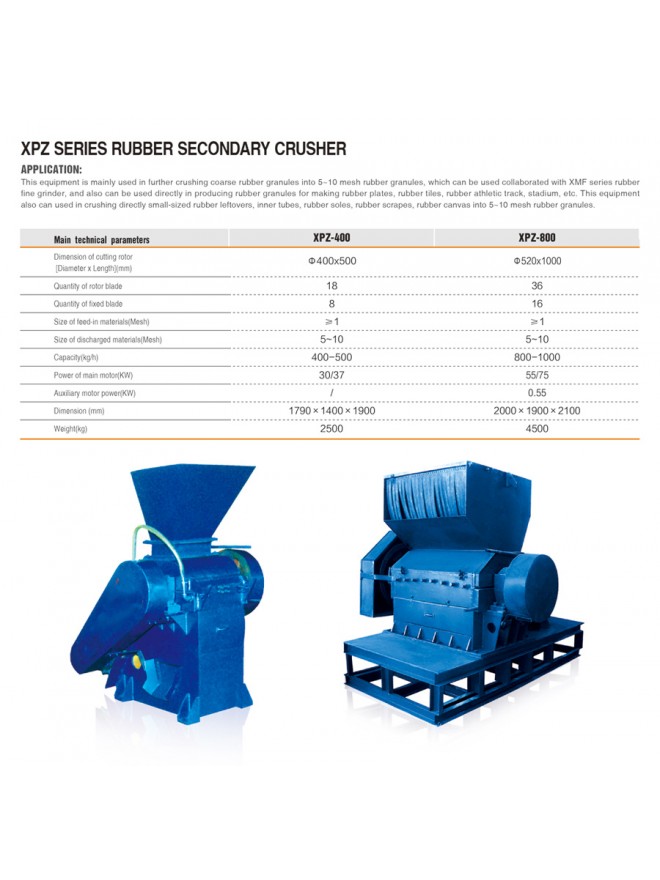

XPZ Series Rubber Secondary Crusher

This equipment is mainly used in further crushing coarse rubber granules into 5-10 mesh rubber granules, which can be used collaborated with XMF series rubber fine grinder, and also can be used firectly in producing rubber granules for making rubber plates, rubber tiles, rubber athletic track, stadium, etc.

This equipment also can be used in crushing directly small- sized rubber leftovers, inner tubes, rubber soles, rubber scrapes, rubber canvas into 5-10 mesh rubber granules.

Product Paramenters

FAQ

Q1. What can recycled tires be used for?

A1: Scrap tires can be ground and mixed with asphalt to pave roads, or shredded for use in landslide repair and embankments.

A1: Scrap tires can be ground and mixed with asphalt to pave roads, or shredded for use in landslide repair and embankments.

These uses keep thousands of tires out of landfills with every project.

Q2. What products are made from recycled tyres?

A2: Innovative uses for recycled tyres

Substitute for gravel. Instead of using gravel, it's possible to use tyre chips instead.

Crumb rubber.

Landfill liners and covers.

Filters for wastewater treatment.

Garden mulch.

Tyre-derived fuel.

Tyre-derived aggregate.

Opt for a greener approach.

Q3. How do shred car tyres?

Q2. What products are made from recycled tyres?

A2: Innovative uses for recycled tyres

Substitute for gravel. Instead of using gravel, it's possible to use tyre chips instead.

Crumb rubber.

Landfill liners and covers.

Filters for wastewater treatment.

Garden mulch.

Tyre-derived fuel.

Tyre-derived aggregate.

Opt for a greener approach.

Q3. How do shred car tyres?

A3:The tyres should be shredded into crumbs or chips, as this will make them easier to resell. The shredder works by rotating knives, either on a single shaft or twin shaft to reduce the size of the tyre so that the volume is greatly reduced down to a pile of

rubber tyre crumb.

Q4. Is tire recycling a profitable business?

A4: In addition to benefiting the environment, used tire recycling can be a profitable business. Millions of used tires provide a

continuous source of supply of recycled tires that are used in three markets: tire-derived fuels, civil engineering applications

and ground rubber applications or rubberized asphalt.

rubber tyre crumb.

Q4. Is tire recycling a profitable business?

A4: In addition to benefiting the environment, used tire recycling can be a profitable business. Millions of used tires provide a

continuous source of supply of recycled tires that are used in three markets: tire-derived fuels, civil engineering applications

and ground rubber applications or rubberized asphalt.

Company Profile

About us